— Healthcare —

Scott Hamilton Proton Therapy

Nashville, Tennessee

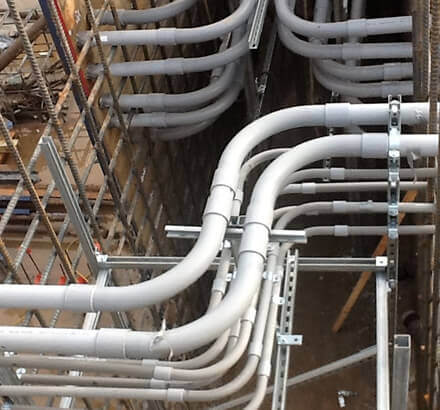

The electrical portion of this project included an advanced underground buildout and complete power distribution to multiple redundant systems, advanced treatment areas, and specialty equipment.

The Proton Therapy project team embraced an early collaborative approach, right from the start. Prior to jobsite mobilization, the Gaylor Electric engineering team delivered 100% BIM coordination. This virtual model played a major role in our project team making intentional choices throughout the design and development phases of this complex build, and aided in a successful pre-plan, corrected trade clashes, and eliminated any major scope of work changes.

The Gaylor Electric fabrication team also worked in tandem with our engineering department to create an in-house replica of the Proton Therapy cyclotron pit. By taking the BIM model, and applying the 3D design to pre-fabrication design, our team was able to construct a physical modular template used to fabricate hundreds of electrical assemblies with complete accuracy and precision.

Award Winner

Build Type

Design-Assist

Project Size

30,700 SF